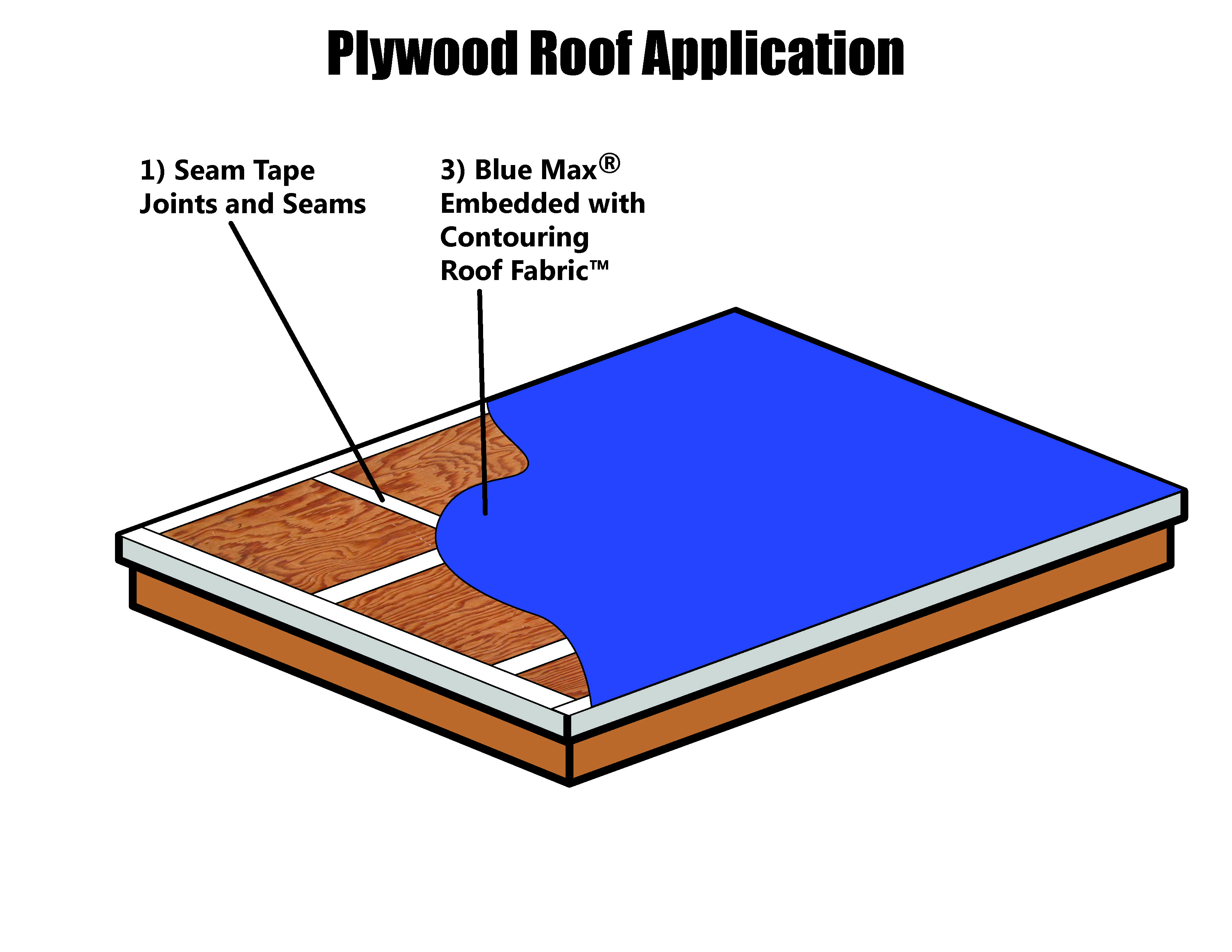

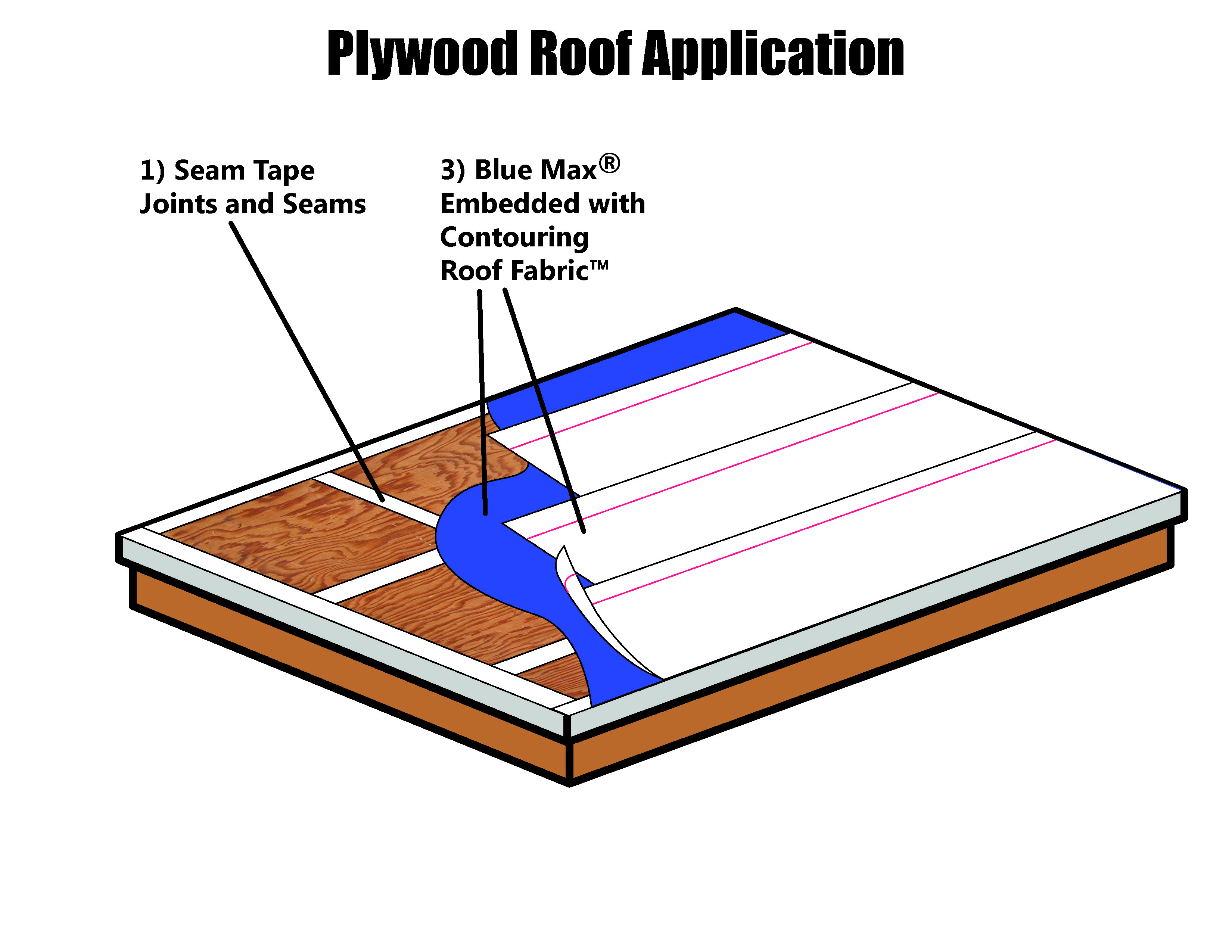

Roof decks, by definition, are decks that exist over living areas. Although the substructure material is different the application method for both a plywood and concrete deck are the same. It used to be that roof deck applications were quite expensive to build and had a multitude of waterproofing and application problems. All that has changed with Ames’ premium, water-based, environmentally friendly, elastomeric, waterproofing, acrylic and rubber coatings. There really is nothing else quite like it out there.

Do not proceed unless you are satisfied.

For product information or technical assistance, call 1-888-345-0809 or contact us via email.

When top coating, keep in mind that white or light-colored coatings will reflect nearly all solar rays and dry at a much slower rate than dark colored coatings. If you live in the northern hemisphere the best time to apply white products is the summer months when there is plenty of sunlight. In contrast, darker coatings absorb more sunlight and dry more quickly.

Prime with 1-2 coats of Ames’ Super Primer. Allow primer to dry completely clear. Apply 2-3 coats of Ames’ Super Elasto-Barrier dual rubber coating. Then apply 2-3 coats of Safe-TDeckor Liquid Granite over Super Elasto-Barrier. Allow proper drying time between coats.